Tools & Supplies

Filter

22 products

Epoxy Countertop Toolkit

Regular price

$13.99

Sale price

$13.99

Regular price

Unit price

/per

3/8 Inch Nap Microfiber Roller Kit

Regular price

$8.99

Sale price

$8.99

Regular price

Unit price

/per

1/8 Inch Square Notch Trowel

Regular price

$5.99

Sale price

$5.99

Regular price

Unit price

/per

3/8 Inch Nap Microfiber Roller Covers

Regular price

From $5.99

Sale price

From $5.99

Regular price

Unit price

/per

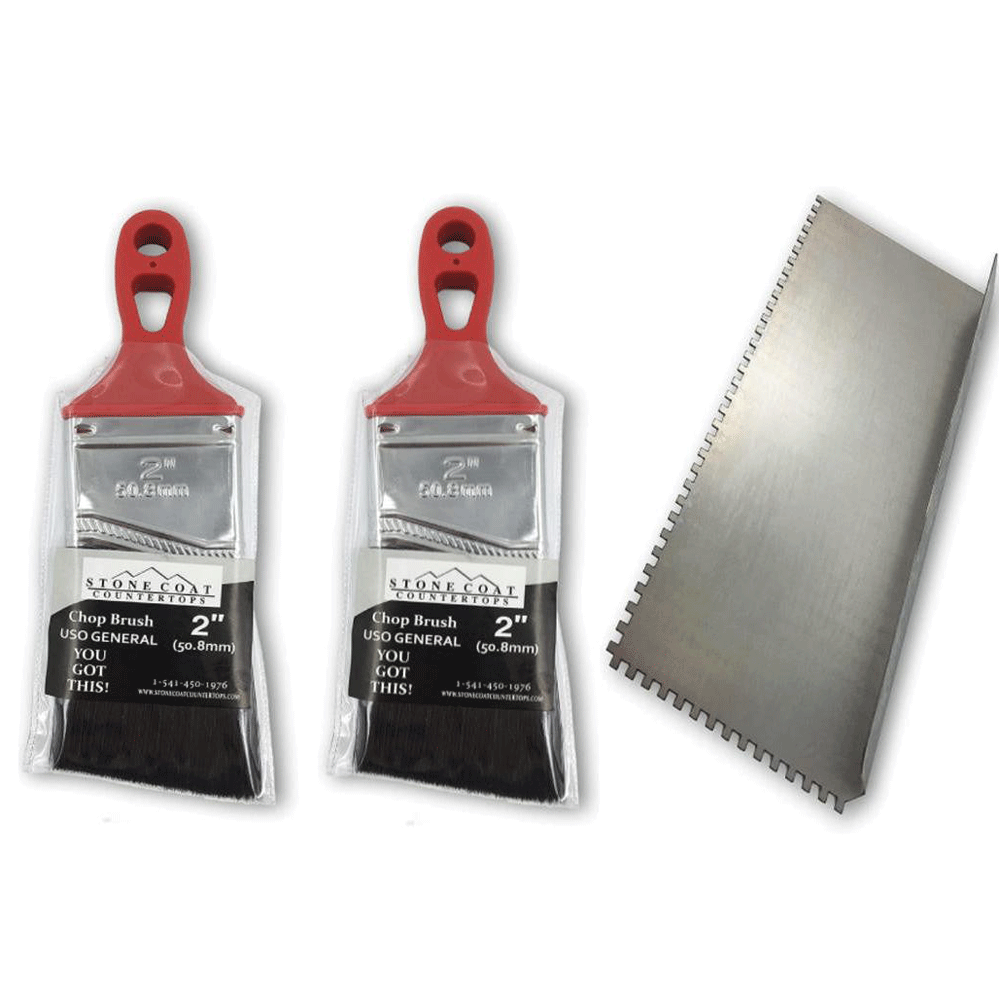

2 Inch Chop Brush

Regular price

$5.99

Sale price

$5.99

Regular price

Unit price

/per

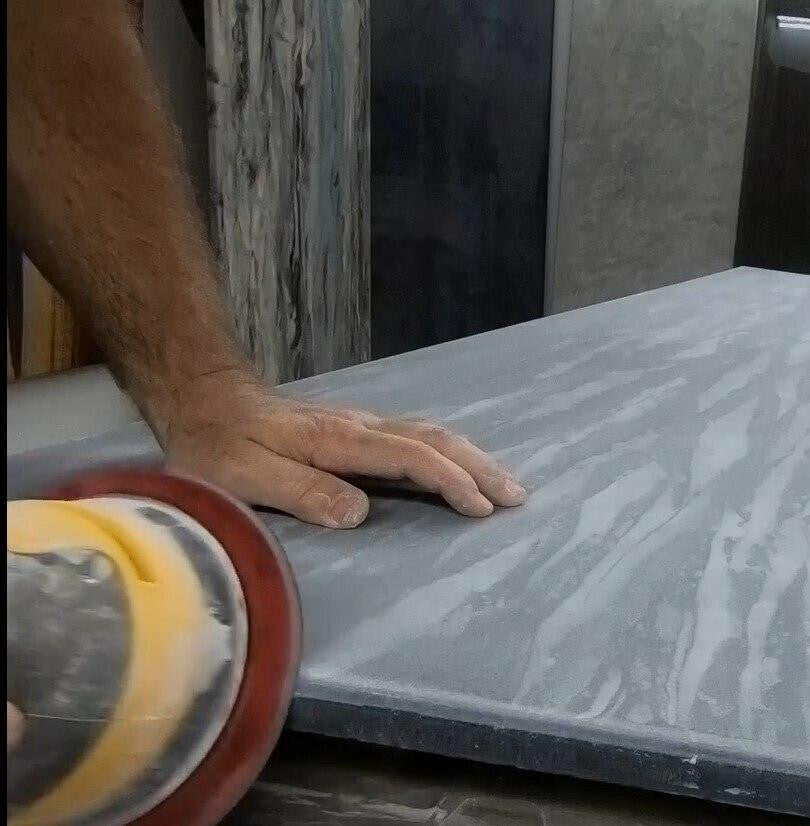

Epoxy Polishing & Cleaning Kit

Regular price

$34.99

Sale price

$34.99

Regular price

Unit price

/per

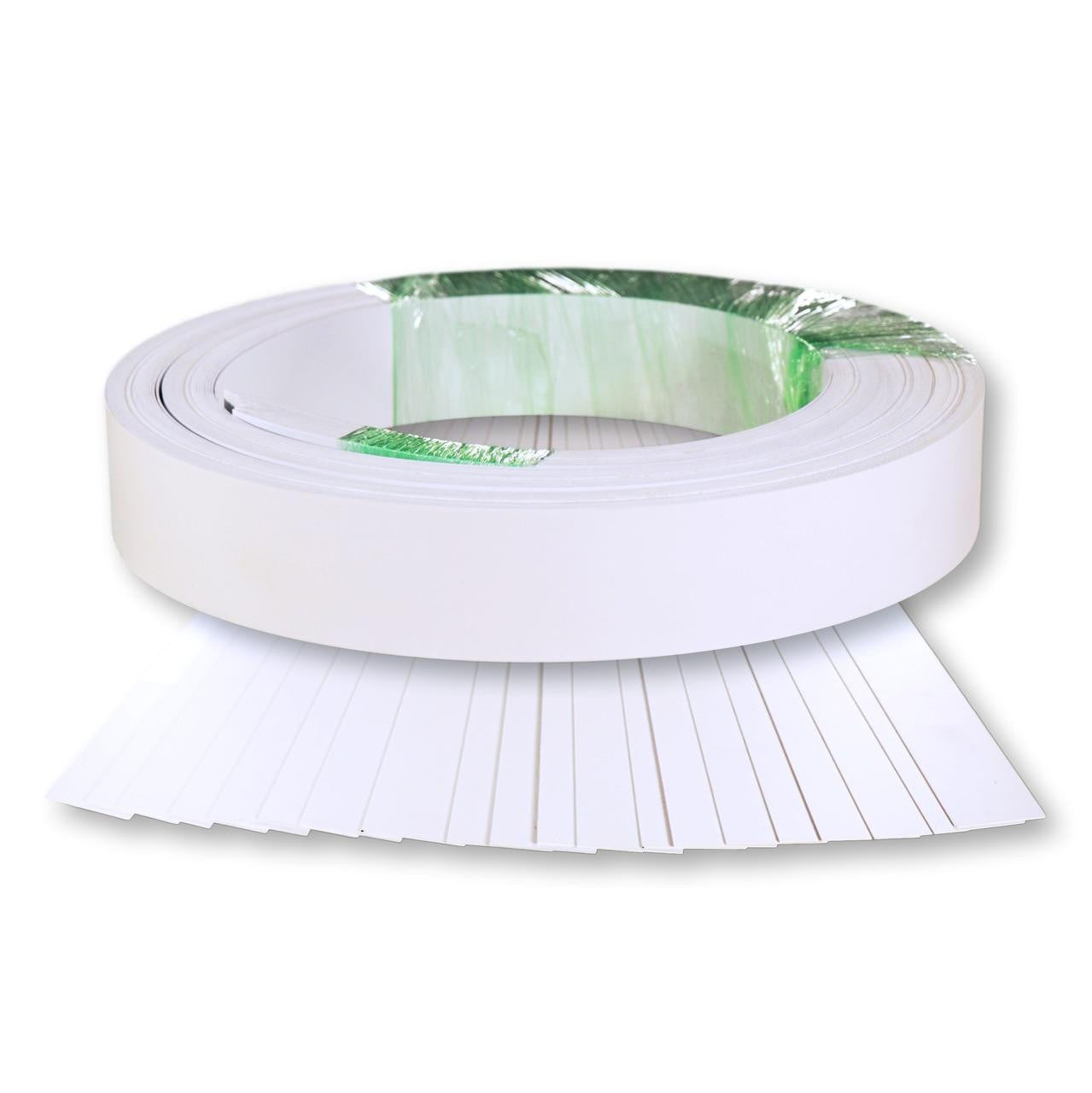

Template Material For Countertops (Roll of 20 Sheets)

Regular price

$43.99

Sale price

$43.99

Regular price

Unit price

/per

Epoxy Thickener

Regular price

$14.99

Sale price

$14.99

Regular price

Unit price

/per

Assorted Grit 5 & 6 Inch Sanding Disc Kit

Regular price

$32.99

Sale price

$32.99

Regular price

Unit price

/per

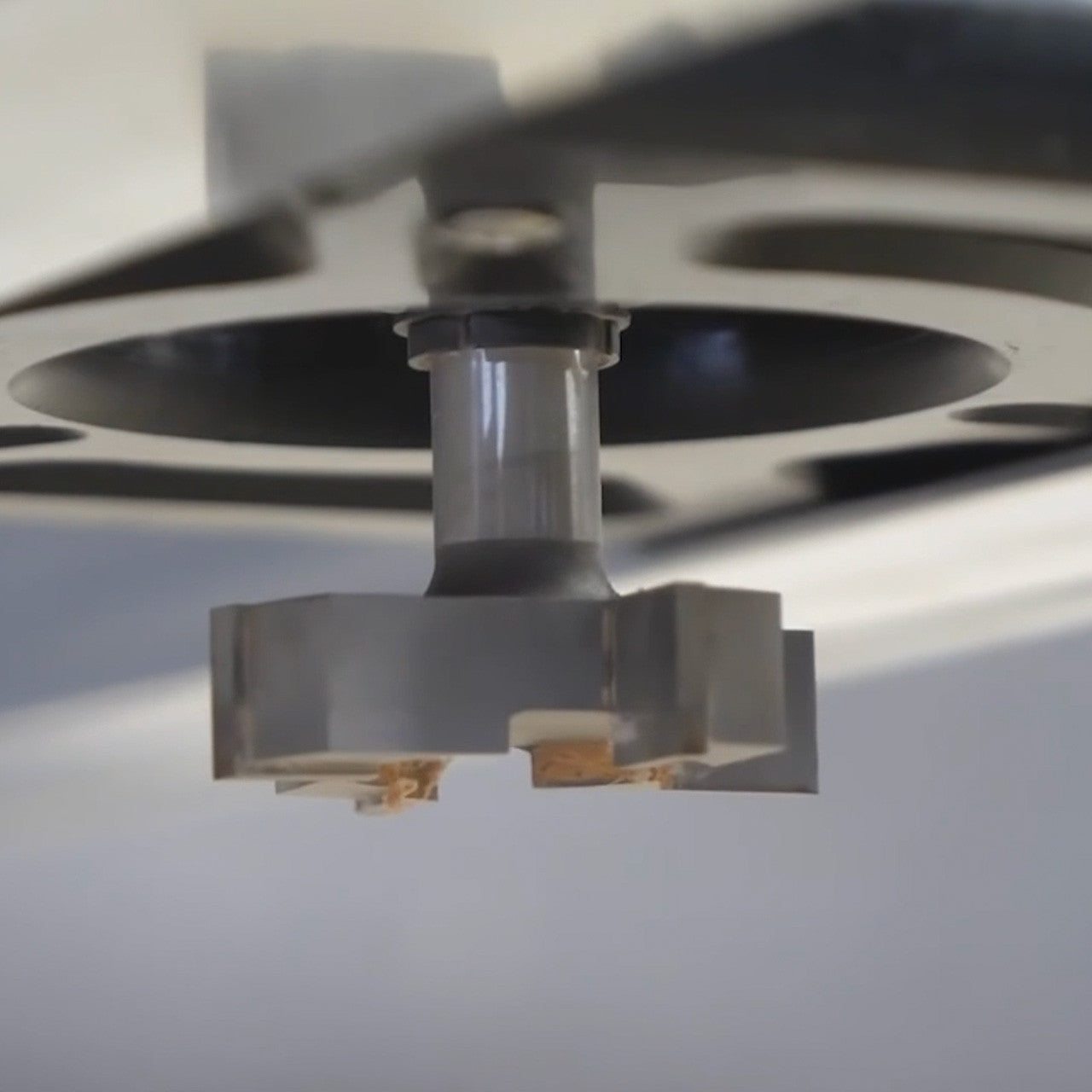

Router Slab Jig

Regular price

$439.99

Sale price

$439.99

Regular price

Unit price

/per

Stone Coat Countertops Measuring & Mixing Cup

Regular price

From $0.99

Sale price

From $0.99

Regular price

Unit price

/per

Durable Fiberglass Mesh

Regular price

$29.99

Sale price

$29.99

Regular price

Unit price

/per

Amazing Resin Remover

Regular price

From $11.99

Sale price

From $11.99

Regular price

Unit price

/per

Non-Skid Floor Additive

Regular price

From $6.99

Sale price

From $6.99

Regular price

Unit price

/per

50 Grit Sanding Discs & Backer Kit

Regular price

$18.99

Sale price

$18.99

Regular price

Unit price

/per

Collection:

Tools & Supplies

Get all your epoxy tools and supplies from Stone Coat Countertops—your experts in epoxy countertops, resin woodworking, and flooring. Our products make it easy to pour directly over your countertop, turning your DIY kitchen or bathroom project into a fun and straightforward experience. Start your project today with Stone Coat Countertops!